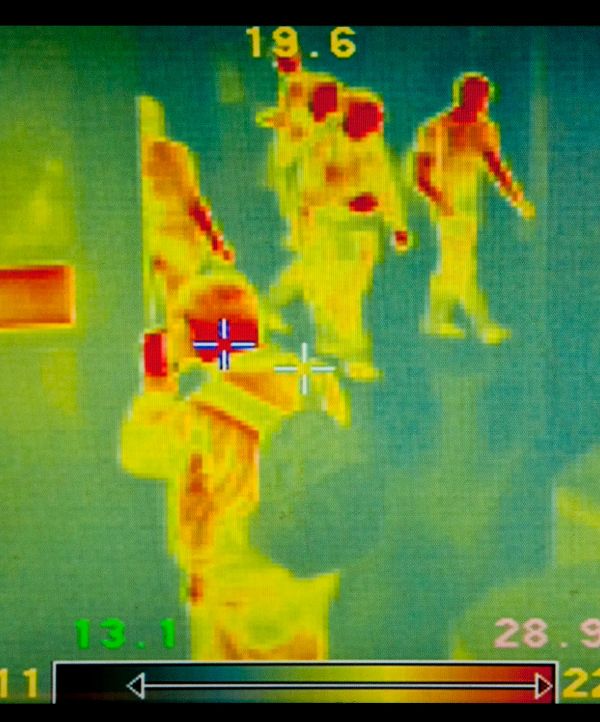

Thermal Imaging

It is available to you as a standalone service or integrated into a regular maintenance program. SAMS help you with a detailed IR assessment, enabling you to manage your facilities for desired performance, extend the life and reliability of your infrastructure-hardware, and ensure the optimum level of system availability.

SAMS uses a digital infrared thermography camera from world leader FLIR, Sweden that captures the integrity of electrical infrastructure and other control equipment, motors, server racks etc. from their heat emissivity, temperature variations and cooling distribution perspective. SAMS IR Thermography Consultants will conduct a thorough survey of the target area/ equipment, gather IR Photos and conduct physical examination. The unique Thermography Health-Check Service is intended to provide a proactive guidance for maintaining the electrical infrastructure and equipment under survey to improve reliability and prevent unplanned downtime. With the gathered site data, SAMS will develop a comprehensive report and analysis that will include recommendations and corrective actions.

Oil

SAMS analysis pay highly attention on levels of the various metals and additives, amount of abrasive solids , grade or thickness and contaminant in oil, by using different examination/ testing modern methods of oil analysis like Spectral Exam, Insoluble Test, Viscosity Test, And Flash Point Test.

It is an integral part of the maintenance plan for power plants, manufacturing plants, trucking companies, construction equipment, aircraft, refrigeration systems, processing and chemical plants, etc. Any piece of equipment that has a lubricating system is an excellent candidate for oil analysis.

SAMS goal of a proactive oil analysis program is to trend gradual changes in fluid properties, contaminants and wear debris so that corrective action can be initiated in a controlled, planned manner.

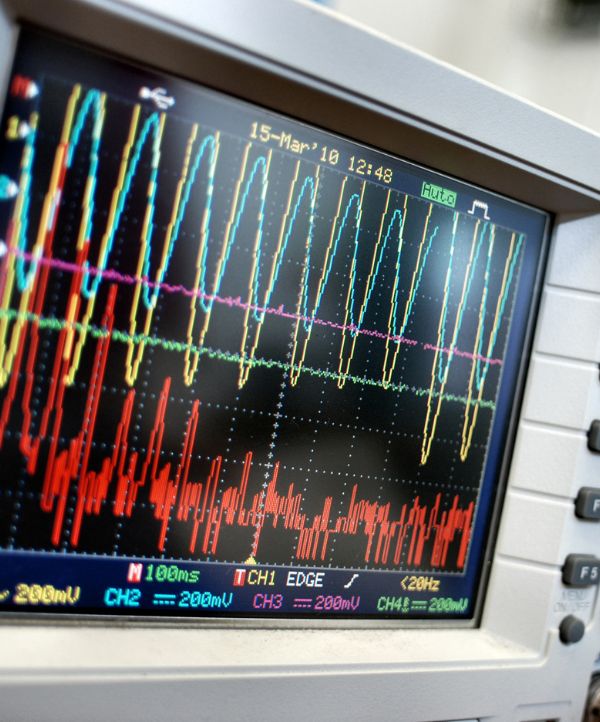

VIBRATION ANALYSIS

SAMS experienced, unbiased specialists will define and forecast equipment problems, needs and goal SAMS focus on maintenance and operations by predicting functional failures, forecasting failure mode and estimating time until failure; conveniently schedule targeted proactive failure interventions and prevent loss of production availability/production capacity/product quality which Improves reliability (mean time to repair, mean time between failure, plant availability and utilization)

SAMS is the company who use vibration analysis technology for our clients to decrease his plant maintenance cost and optimize returns, reduce labour and material cost needed for preventive maintenance routines, minimize energy consumption, increase product quality,increase production capacity, reduce spare parts inventory, provide consistent equipment performance, provide reliable production, increase equipment availability, reduce downtime, extend asset life, reduce overhauls, prevent maintenance overkill and maintenance collateral damage, improve repair scheduling, save overtime cost by using helpful vibration analysis technology .